Hollow stainless steel balls are common spherical objects that are often used to make mechanical parts, industrial accessories, home decoration, etc. Hollow stainless steel balls have outstanding features such as beauty, corrosion resistance, and wear resistance, and their processing technology is also very critical.

Stainless steel spheres are very common in life. This article discusses the production process, characteristics, and applications of stainless steel spheres.

1.Production process of stainless steel sphere

Step 1

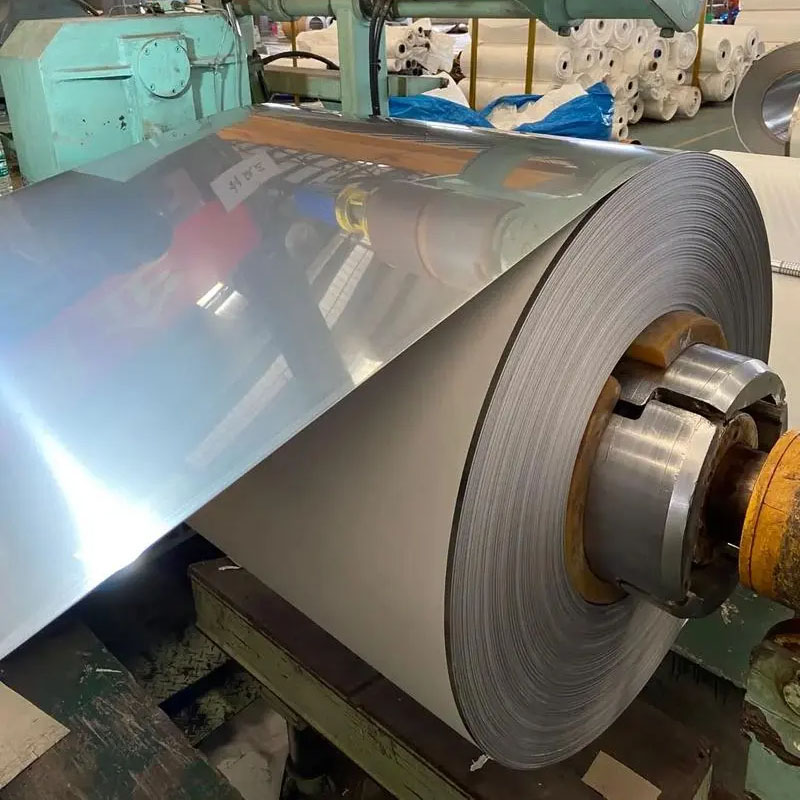

Choose appropriate stainless steel materials, such as 304, 316, 201 and other different grades of stainless steel materials. According to different requirements, different stainless steel materials are selected to ensure the quality of hollow stainless steel balls.

Step 2

First, cut the stainless steel material into blocks. When cutting, you need to pay attention to the control of the tool pressure, cutting speed, etc. to avoid damage to the stainless steel material.

Step 3

The cut stainless steel material is processed into a round blank, which can be processed by stamping, spinning and other methods. The hollow part needs to be processed by drilling, discharge wire cutting and other processing methods.

Step 4

The finished round blank is ground and polished. During the grinding process, attention needs to be paid to ensuring the flatness and precision of the machined surface. Polishing can improve the surface smoothness of the hollow stainless steel ball.

Step 5

Carry out final cleaning and quality inspection work. Cleaning can be carried out by pickling, alkali washing, electrolysis and other methods to ensure that the surface of the hollow stainless steel ball is clean and free of impurities. Quality inspection mainly checks whether there are cracks, pinholes and other defects in the product, and keeps records.

To sum up, the processing technology of hollow stainless steel balls is inseparable from material selection, blank production, processing, grinding and polishing, as well as final cleaning and quality inspection.

2.Characteristics of stainless steel sphere

Strong corrosion resistance:

Stainless steel balls are made of stainless steel and have excellent corrosion resistance. They can still maintain good performance in harsh environments such as moisture, acid and alkali.

High strength:

Stainless steel material has high tensile strength and hardness, so the stainless steel balls made have high strength and can withstand greater pressure and load.

Good wear resistance:

The surface of the stainless steel ball has been specially treated and has good wear resistance, and can be used for a long time in an environment with high friction without damage.

Beautiful and elegant:

The stainless steel ball has a smooth surface, a metallic texture, and a beautiful and elegant appearance, which can improve the quality of the product.

3.Application of stainless steel sphere

Construction field:

Stainless steel balls are often used in indoor and outdoor decoration, such as stair handrails, railings, door handles, etc. Its corrosion resistance and beautiful appearance make it the first choice among decorative materials.

Chemical industry:

Stainless steel balls can be used to manufacture chemical equipment, such as reactors, storage tanks, pipelines, etc. Its anti-corrosion performance can ensure the long-term stable operation of the equipment in harsh environments such as acid and alkali.

Automobile manufacturing field:

Stainless steel balls are widely used in automobile manufacturing. It can be used in mufflers, tailpipes and other components in automobile exhaust systems because of its high temperature resistance and good corrosion resistance.

Aerospace field:

The aerospace field has extremely high requirements for materials. Stainless steel balls are widely used in aircraft manufacturing and spacecraft components due to their corrosion resistance and strength.